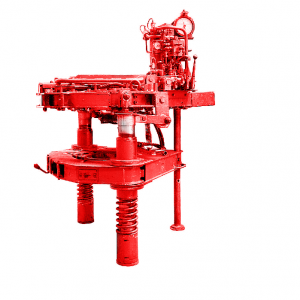

Weatherford TorkWrench 10-100 Iron Roughneck

Weatherford’s patented TorkWrench® 10-100 Iron Roughneck is the performance leading hydraulic iron roughneck in its class, providing up to 100,000 ft-lb of torque for the toughest makeup and breakout operations. The TorkWrench® 10-100 has a compact design with fewer moving parts that increase overall reliability and provide outstanding high-speed breakout performance.

The TorkWrench® 10-100 can be used for most oilfield connections including drill string components, tools, packers, couplings, and valves. Ancillary features include the PowerFrame™, PowerArm® 2.1, PowerScope™ automated tong positioning systems, which greatly increase productivity by providing the means to work offline to makeup and breakout drill bits and bottom hole assemblies clear of the rotary table and out of the critical path.

Weatherford’s patented TorkWrench® 10-145 Iron Roughneck is the performance leading hydraulic iron roughneck in its class, providing up to 145,000 ft-lb of torque for the toughest makeup and breakout operations. The TorkWrench® 10-145 has a compact design with fewer moving parts that increase overall reliability and provide outstanding high-speed breakout performance. The TorkWrench® 10-145 can be used for most oilfield connections including drill string components, tools, packers, couplings, and valves. Ancillary features include the PowerFrame™, PowerArm® 4.4, PowerScope™ automated tong positioning systems, which greatly increase productivity by providing the means to work offline to makeup and breakout drill bits and bottom hole assemblies clear of the rotary table and out of the critical path.

Applications

1.Running drill pipe, tripping standard- or premium-connection drill pipe, offline stand building, and bit breaking

2.Bottom hole assembly makeup and installation

Options

- PowerFrame™ 2 (mechanized version)

- PowerFrame™ 3 (manual operated version or mechanized version)

- PowerScope™ system

- PowerArm® 2.1

- HiPer™ remote control system (mechanized version)

- Electric and hydraulic power units

- Electronic torque gauge (ExTG™)

- Stabbing guide and tool joint finder (for remote-controlled all-in-one version)

- Automated thread cleaning and doping (for remote-controlled all-in-one version)

- Automated mud bucket (for remote-controlled all-in-one version)

Features, Advantages and Benefits

1.High-torque wrenching and spinning units combine to provide faster makeup and breakout operations

2. Three-jaw gripping system enables equal load distribution and easy jaw and die exchange, eliminating shear forces on tool joints and reducing backup clamping pressure while spinning

3.Pneumatic “intelligent” control box can be disconnected from tong unit and relocated into safe area

4.Free-floating spinning system follows the movement of pipe, protecting the tool joint and minimizing drill pipe damage caused by conventional systems

Related products

-

Hydraulic Tubing & Casing Tongs & Iron Roughneck

Weatherford 16-25 High-Torque Casing Tong

-

Hydraulic Tubing & Casing Tongs & Iron Roughneck

Weatherford E-Power Unit 55kW-EHPU

-

Hydraulic Tubing & Casing Tongs & Iron Roughneck

Weatherford E-Power Unit 37kW-EHPU

-

Hydraulic Tubing & Casing Tongs & Iron Roughneck

Weatherford Diesel Power Unit with Spring Starter

-

Hydraulic Tubing & Casing Tongs & Iron Roughneck

Weatherford 5.5-15 Hydraulic Tubing And Casing Tong