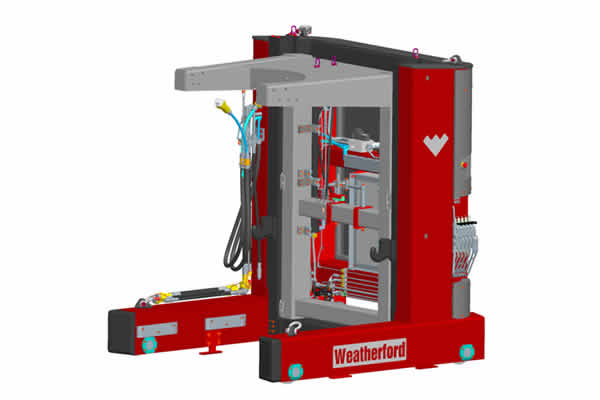

Weatherford PowerFrame Positioning Device

PowerFrame 2 And PowerFrame 3

Weatherford’s track-mounted tong positioning system PowerFrame™2 is designed to house and position the entire family of Weatherford mechanized hydraulic power tongs, including the iron roughneck, casing, tubing, drill pipe, and production riser tongs. The PowerFrame™2 system can be remotely operated for safety and employs programmable logic control (PLC) technology for efficiency and reliability.

This PowerFrame system is rugged and reliable and has a small footprint, which makes it ideally suited for new-build rigs and refurbishment applications.

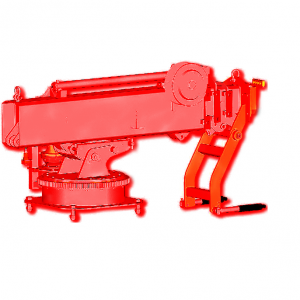

Weatherford’s PowerFrame™3 system offers a first and simple step toward mechanizing tubular-handling operations. This cost-effective tong manipulation frame is designed to position power tongs on the rig floor from a standby position to well center and/or mousehole. The lightweight frame is adaptable to most rig floor designs. One person can set up the entire system, which is compatible with Weatherford’s tubing, casing, and drill pipe tongs. The tong, with backup, is installed to, and suspended from, the PowerFrame™3. The frame is controlled by the valve section of the tong, eliminating the need for an additional control system or power unit. Depending on the tong configuration and project requirements, the remote control of the system can be manual, pneumatic, or by programmable logic controller (PLC). Any experienced power tong operator can run the PowerFrame™ III system.

Applications

1.Running drill pipe, casing, tubing, and production risers

2.Offline stand building and bottomhole assembly (BHA) makeup and installation

3.Drillbit makeup and breakout

4.New-build rigs and refurbishment applications

5.Drillbit makeup and breakout

6.Offline stand building and bottomhole assembly (BHA) makeup and installation

7.Drillbit makeup and breakout

Options

1.PowerFrame™ 3-Tail-in guide is a gantry-mounted hydraulic cylinder with a roller head to align the pipe and a separate control panel for easier thread alignment. The stroke of the tail-in cylinder is 55 ‘‘ (1,400 mm)

2.PowerFrame™ 3-Tong gantry frame is available in a standard version and in heavy-duty configuration to accommodate heavier tongs (maximum 8,100 lb/3,700 kg)

3.PowerFrame™ 3- A positioning cylinder, with 78.7“ (2,000-mm) stroke, is available for moving the PowerFrame™ 3 system between well center and park position

Features, Advantages and Benefits

1.Remote operation requires fewer rig floor personnel, improving safety and reducing operating costs

2. Plug-and-play technology enables quick tong change-out, saving time during operations

3.BHA makeup capability reduces required onboard storage

4.Use with Weatherford’s patented TorkWinder® drill pipe tong (photo) provides the most efficient available premium-connection (XT, XTM, WT) drill pipe makeup

5.Compatibility with the entire family of Weatherford mechanized power tongs reduces capital investment, making the system very cost effective

6. Design incorporates multiple safety cutoffs and interlocks, decreasing the risk of accidents and injuries

7. Memory feature positions the tong horizontally and the connection finder automatically positions the tong vertically for extremely efficient tong positioning

8.Customizable for specific rig requirements, the system also fits existing roughneck rails, minimizing costly rig modifications

9.System allows offline makeup, improving operational efficiency

10.Optional multitrack system for PowerFrame™2 operation on different rail widths

11.PowerFrame™2 System contains two hydraulic motors for horizontal movement on the rails and four hydraulic lift cylinders for vertical lifting (two tong carrier and two telescope lift cylinders). Two lift cylinders are mounted between the telescope and chassis to allow a telescope elevation of max. 35.4- inch/900 mm. Two lift cylinders are mounted between the carrier and telescope to allow an additional carrier elevation of max. 41.6-inch/1050 mm, including thread compensation device

12.Design enables advanced integration with rig safety systems, including the Varco V-ICIS system

13.PowerFrame™ 3 system serves as a single tong-positioning device to cover all tubing, casing, and drill pipe operations requiring Weatherford tongs with up to 3.7-ton capacity. This versatility eliminates the need for additional positioning devices in this capacity range

14.Compatibility with most Weatherford mechanized power tongs reduces capital investment, making the PowerFrame™ 3 system a cost-effective tong handling solution

15.PowerFrame™ 3 is controlled by the valve section of the tong, eliminating the need for an additional control system, which reduces costs while enhancing ease of operation

16.PowerFrame™ 3 System is operated by one hydraulic cylinder for horizontal movement on the rails and two hydraulic lift cylinders for vertical lifting of the gantry, for a maximum lifting stroke of 39.4 ‘‘ (1,000 mm) to accelerate operations

17.PowerFrame™ 3 System features a special lifting arrangement to provide maximum protection for the operator under high-load conditions

Related products

-

Remote Control Systems & Positioning Devices

Weatherford PowerScope Positioning System

-

Remote Control Systems & Positioning Devices

Weatherford StabMaster System

-

Remote Control Systems & Positioning Devices

Weatherford Hiper Remote Control System

-

Remote Control Systems & Positioning Devices

Weatherford ExTG Torque Monitoring & Control System

-

Remote Control Systems & Positioning Devices

Weatherford PowerArm 2.1 Positioning Device