Weatherford Centralizers

Weatherford Centralizers

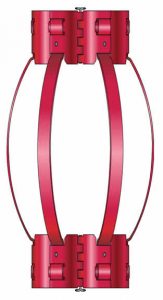

Weatherford’s latch-on drillpipe centralizers, when properly placed, are designed to optimize inner-string cementing operations by centralizing drillpipe, even in horizontal applications. Providing excellent downhole durability and performance, the specially designed centralizers feature heat-treat ed, spring-steel bow springs that are lap-welded to rigid end collars. The centralizers provide the necessary standoff and centralization to ensure that the specialty inner-string stinger is centered in the casing and properly aligned with the corresponding float equipment. The rigid end collars provide solid support for the end bands and latch on to the drillpipe for easy installation. The centralizer is available in a variety of sizes for use with 3 1/2- to 6 5/8-in. drillpipe and available with oversized bows to accommodate a variety of casing sizes. The centralizer is recommended for use with Weatherford’s friction-lock stop collar Model JH5 or the set-screw stop collar Model J10S to prevent axial movement and drillpipe scarring.

ed, spring-steel bow springs that are lap-welded to rigid end collars. The centralizers provide the necessary standoff and centralization to ensure that the specialty inner-string stinger is centered in the casing and properly aligned with the corresponding float equipment. The rigid end collars provide solid support for the end bands and latch on to the drillpipe for easy installation. The centralizer is available in a variety of sizes for use with 3 1/2- to 6 5/8-in. drillpipe and available with oversized bows to accommodate a variety of casing sizes. The centralizer is recommended for use with Weatherford’s friction-lock stop collar Model JH5 or the set-screw stop collar Model J10S to prevent axial movement and drillpipe scarring.

Applications

- Stab-in or screw-in inner string cementing operations

Features, Advantages and Benefits

- The centralizer, when properly placed, provides centralization of drillpipe, ensuring successful inner-string cementing operations

- End collars are manufactured with a unique ribbed design, providing rigidity to the bands and protection for the bow springs

- The high-quality, spring-steel bows are heat-treated, enabling the bows to return to their original shape after passing restrictions, further contributing to optimum centralization

- Latch-on end collars feature an integral hinge that folds to the inside, adding strength and eliminating interference during run-in

Weatherford’s nonweld bow-spring centralizers are designed to centralize casing or tubing in the wellbore during running and cementing operations. With over 50 years of field experience and laboratory testing, the nonweld spring-bow centralizer features high-quality, spring-steel bows that are attached to integrated, hinged end collars with locking tabs. The hinged design enables the end collars to be latched onto casing over a stop collar, if desired, for easy installation. The centralizer should be fitted over a st op collar to ensure the tool is pulled in and out of the wellbore. The nonweld design provides reliable downhole performance in cased-hole or openhole applications. The bows provide maximum standoff to achieve the most efficient displacement of mud and cement. Nonweld bow-spring centralizers are available in several bow heights and sizes, assuring optimum restoring force and providing a variety of bow configurations for special applications. During the planning phase, Weatherford’s CentraPro Plus® software is recommended to ensure optimum centralizer quantity and placement with minimized friction forces.

op collar to ensure the tool is pulled in and out of the wellbore. The nonweld design provides reliable downhole performance in cased-hole or openhole applications. The bows provide maximum standoff to achieve the most efficient displacement of mud and cement. Nonweld bow-spring centralizers are available in several bow heights and sizes, assuring optimum restoring force and providing a variety of bow configurations for special applications. During the planning phase, Weatherford’s CentraPro Plus® software is recommended to ensure optimum centralizer quantity and placement with minimized friction forces.

Applications

- Tubing or casing applications

- Vertical and deviated wells

- Wells where rotation capabilities are not required

- Can be run inside casing or in openhole

Features, Advantages and Benefits

- High-performance bows provide maximum standoff in multiple locations of the annulus, providing the best possible conditions for primary cement to achieve zonal isolation, reducing remedial cementing operations and costs

- All common centralizer sizes have been tested and validated to meet American Petroleum Institute (API) 10D requirements, providing reliability and durability during operations

- Nonwelded design can withstand most wellbore environments, providing operational flexibility

- Bow configurations are available in various heights and sizes suitable for most applications, ensuring operational flexibility

- Locking tabs secure the high-quality, spring-steel bows to the hinged collars, bearing the load force of the centralizer for a reliable downhole performance

- Bows and hinged collars are stocked at most locations, enabling the centralizers to be assembled to specifications quickly

Related products

-

Casing Accessories & Thread Locking Compounds

Weatherford Stab-In Arrangement

-

Casing Accessories & Thread Locking Compounds

Weatherford Eliminator Series Stage Tools

-

Casing Accessories & Thread Locking Compounds

Weatherford Cement Wiper Plugs

-

Casing Accessories & Thread Locking Compounds

Weatherford Sure-Seal 3 Float Shoes

-

Casing Accessories & Thread Locking Compounds

Liquid-O-Ring 250 Liqui-Lok Thread Locking Compound