Liquid-O-Ring 235 Biodegradable Tool Joint & Drill Collar Compound

Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound is a non-metallic compound that is recommended for use on tool joints, drill collars, and other rotary shouldered connections. Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound is recommended as an alternative to conventional zinc, copper, lead, or Teflon®** compounds. The absence of metals eliminates corrosion problems, making 235 Biodegradable Tool Joint and Drill Collar Compound the ideal tool joint and drill collar compound for today’s stringent environmental concerns. Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound meets the objective for eliminating hazardous materials in the work place, as presented in OSHA Communication 29 CFR 1910.1200. It meets torque break-out, circumferential tightening, and makeup torque as recommended by tool joint manufacturers. Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound is designed for drilling hard formations, deep drilling, breaking in new tool joints, directional drilling, crooked holes, and other high torque conditions. Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound has passed the LC-50 toxicity test.

Applications

- THREAD PREPARATION: MAKE SURE PIPE THREADS ARE CLEAN AND FREE OF ALL CONTAMINANTS. DO NOT apply 235 Biodegradable Tool Joint and Drill Collar Compound before proper conditioning has been done to pipe which has been exposed to H2 S, CO2, or downhole chemicals. Carefully wash threads with Aqua Cure™ 690 to remove any salt deposits, residual chlorine from thread cutting operations, dirt, and grease. Use a stiff or wire brush to remove all rust and corrosion. DRY THREADS COMPLETELY BEFORE APPLICATION. All residual water from cleaning procedure, re-threading operations or hydrostatic testing should be completely dried and treated using moisture displacer, such as 130 Water Displacer and Corrosion Inhibitor

- APPLICATION INSTRUCTIONS:Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound should be applied with a #2 Dope Brush or other equipment specifically designed for use with thread compounds (avoid using a paint brush). Use the dope brush bristles to force the compound into the roots of the threads. Take care to cover the entire threaded area. A VISUAL INSPECTION IS ADVISED. For optimum protection apply 235 Biodegradable Tool Joint and Drill Collar Compound to thread protectors as well. If these procedures are not followed, corrosion and pitting may occur

- INSPECTION: One month after application of Liquid-O-Ring 235 Biodegradable Tool Joint and Drill Collar Compound, thread protectors should be randomly removed and inspected for corrosion. Subsequent inspections are recommended every three months

Features, Advantages and Benefits

1.Biodegradable

2.Metal-free

3.Petroleum hydrocarbon-free

4. Inhibits corrosion

5.Resists washouts

6.Water repellent

7.Non-toxic

8.Environmentally safe

9.Friction factor of 1 as per API

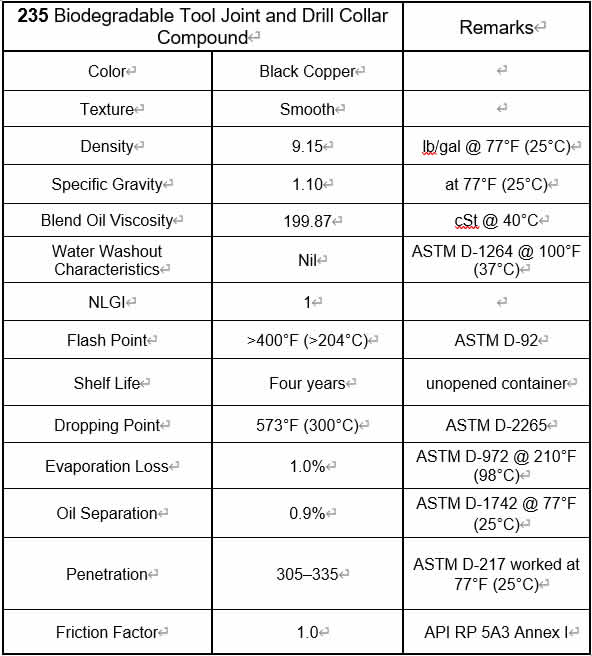

Typical Observations

Related products

-

Thread Compounds For Tubing&Casing&DP

Liquid-O-Ring 167ML50 PREMIUM ANTI-SEIZE LUBRICANT

-

Thread Compounds For Tubing&Casing&DP

Liquid-O-Ring 326 OCR Modified Thread Compound

-

Thread Compounds For Tubing&Casing&DP

Liquid-O-Ring HT-2001 Ultra High-Temp Anti-Seize Compound(1093°C)

-

Thread Compounds For Tubing&Casing&DP

Liquid-O-Ring 4000 OCR Modified Lead & Zinc-Free Thread Compound

-

Thread Compounds For Tubing&Casing&DP

Liquid-O-Ring 318 OCR Modified Premium, Metal-Free Thread Compound