Casing and casing string

Oil well casing is made of high-quality steel seamless pipe or welded pipe, both ends are machined with conical threads. Most casing is made up of a casing string connected by a casing collar. Casing strings are used to seal exposed rock in well walls. Oil well casing has its own special standards, and each casing should meet the standards. The casing standard used in our country is similar to the API (American Petroleum Institute) standard.

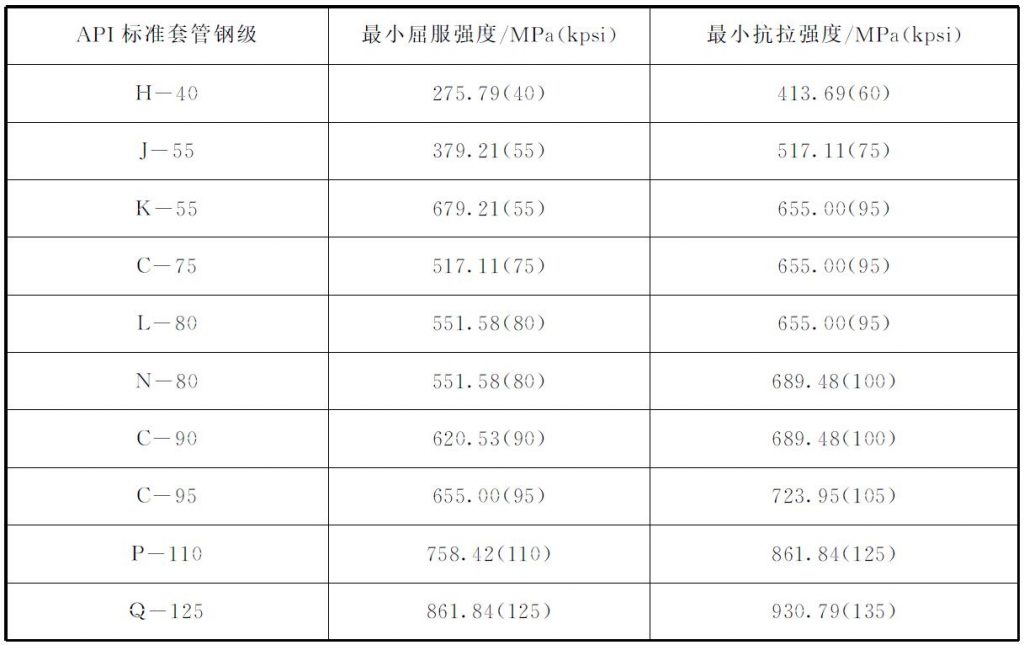

The API standard stipulates that the steel of the casing body should reach the specified strength, which is expressed by steel grade. The API standard does not require the chemical properties of the casing steel, but the minimum yield strength of the steel should be guaranteed, which is 1000 times the minimum yield strength of the casing steel in kpsi (1 bf/in²). API standard the casing steel grade is divided into :H, J, K, N, C, L, P, Q eight kinds of a total of 10 grades. See the following table:

API standards require casing outer diameter to meet a certain size, commonly used standard casing outer diameter from 114.3 mm(4½ in) to 502 mm(20 in) a total of 14 types:

114.30 mm(4½ in); 127.00 mm(5 in); 139.70 mm(5½ in); 168.27 mm(65⁄8 in); 177.80 mm(7 in); 193.67 mm(75⁄8 in); 219.07 mm(85⁄8 in); 244.47 mm(95⁄8 in); 273.05 mm(103⁄4 in); 298.44 mm(113⁄4 in); 339.71 mm(133⁄8 in); 406.40 mm(16 in); 473.08 mm(185⁄8 in); 508.00 mm(20 in);

Casings have different wall thicknesses. API standard specifies the wall thickness range of various casings in 5.21-16.13mm. Usually, the wall thickness of small-diameter casing is smaller, and the wall thickness of large-diameter casing is larger. In addition to the standard steel grade and wall thickness, there are non-standard steel grades and wall thicknesses, which are also allowed by the API standard.

The connection threads of the casing are conical threads. There are four kinds of connection threads for API standard casing: short round thread (STC), long round thread (LTC), trapezoid thread (BTC), and straight thread (XL). In addition there are non-standard threads.

The taper of the round thread is 1:16 and the pitch is 3.175 mm (8 buttons per inch). The taper of the trapezoidal thread is 1:16 (OD <16 in) and 1:12 (OD ≥16 in), and the pitch is 5.08 mm (5 buttons per inch). Casing string is usually composed of the same outer diameter, the same or different steel grades and different wall thickness of casing with collar connection, should meet the requirements of strength and production.

Force analysis of casing string and casing strength

The casing string is subjected to various forces after being run into the well. In different types of Wells or in different production periods of a well, the force on the casing string is different. The basic load on the casing string can be divided into axial tension, external extrusion pressure and internal pressure. The stress analysis of casing string is the foundation of casing strength design. The basic load of casing should be considered according to the most dangerous condition of casing.

Casing strength design principles

The strength design of the casing string is based on the external load on the casing to establish a safe balance relationship according to the strength of the casing:

Casing strength ≥ external load X safety factor

The strength design of casing string is based on the requirements of the technical department, after determining the outer diameter of the casing, casing with different steel grades and wall thickness is selected according to the size of the external load on the casing and a certain safety factor, so that the casing string can establish the above expressed relationship on each dangerous section. The design must ensure that the maximum stress acting on the casing is within the allowable range throughout the life of the well.

Design principles should consider the following three aspects:

It should be able to meet the needs of drilling operations, oil and gas reservoir development and production reservoir reconstruction.

There should be a certain reserve capacity when bearing external load;

Economical;

In the casing design, our country has made certain provisions. The provisions on the safety factor are; Safety factor Sc=1.0; Safety factor against internal pressure Si=1.1; Casing tensile strength (anti-slip) safety factor St=1.8.

Commonly used casing string strength design method

Each country has its own design method of casing string strength according to its own conditions. The most common methods are equal safety factor method, boundary load method, maximum load method, AMOCO method, West Germany BEB method and the former Soviet Union method.

Design characteristics of each layer of casing

For the design of surface casing, oil casing and technical casing, each has its own design characteristics and design emphasis.

Design characteristics of surface casing

Surface casing is a layer of casing that is lowered to consolidate the loose surface layer and install the wellhead blowout prevention device. The surface casing also bears some of the weight of the lower casing. Therefore, the design feature of the surface casing is to withstand the formation pressure during the downhole gas invasion or blowout, and the casing design mainly considers the internal pressure resistance to prevent the casing from being crushed and burst under high pressure when the well is shut in.

Design characteristics of technical casing (CsTeC)

Technical casing is run in order to seal complex formation, and in subsequent drilling, it must withstand the internal pressure during blowout and the collision and wear of the drill tool. The design characteristics of the casing are not only to have a high internal pressure strength, but also to have the ability to resist the impact of drilling tool wear.

Design characteristics of oil casing

Reservoir casing is a layer of casing that is run last in an oil and gas well and into which tubing is run for oil production. Because the casing depth is large, anti-extrusion is the focus of the lower casing. The casing should be considered separately according to the problems it may encounter in production. For example, some Wells are used for water injection, and some need to be fractured or acidified in oil production, the casing may also bear greater internal pressure, and the internal pressure resistance strength of the oil casing of such Wells should be strictly checked. Some are mainly hot steam injection for thermal mining, casing will expand by thermal action for a long time, resulting in greater compressive stress, so the design should consider the tension safety factor when applying pre-tensile stress. (2023-11-23)