Anaerobic glue is one of our more common adhesives. Anaerobic adhesive is a single-component sealing adhesive made by using the principle of oxygen to inhibit the polymerization of free radicals, which can be used for bonding and sealing. When the adhesive surface is isolated from the air and can be rapidly polymerized and cured at room temperature under the condition of catalysis. The screw glue is mainly used in energy, electrical appliances, electronics, aviation machinery, automotive industry. You’ll see it everywhere there’s a screw. Generally, the screw is locked and placed on the mother screw. Let it slowly cure, on the one hand, so that the screw will not fall off during the operation, on the other hand, it has the effect of rust prevention.

- Application range of screw glue and anaerobic glue

Because of its unique anaerobic adhesive curing characteristics, it can be used in locking, sealing, fixation, bonding, plugging and other aspects. Anaerobic glue has become an indispensable liquid tool in the machinery industry. In energy, aerospace, military, automotive, machinery, electronics, electrical and other industries have a wide range of applications.

Screw glue is used in aircraft, ships, cars, vehicle electronics and other screws in various industries. Other such as TV, washing machine, video player, motorcycle, camera, video camera, all kinds of household appliances and sound machine screws can be used. - What is the difference between full and semi-solid screw glue?

Full fixing is also known as the air screw fixing agent, generally used in the screw, fixed after hypoxia can not be removed, semi-fixed is generally used in the screw lock after the point in the appearance of the screw for fixing, so as to facilitate removal in the future. - The role of screw glue and anaerobic glue

Lock and keep loose

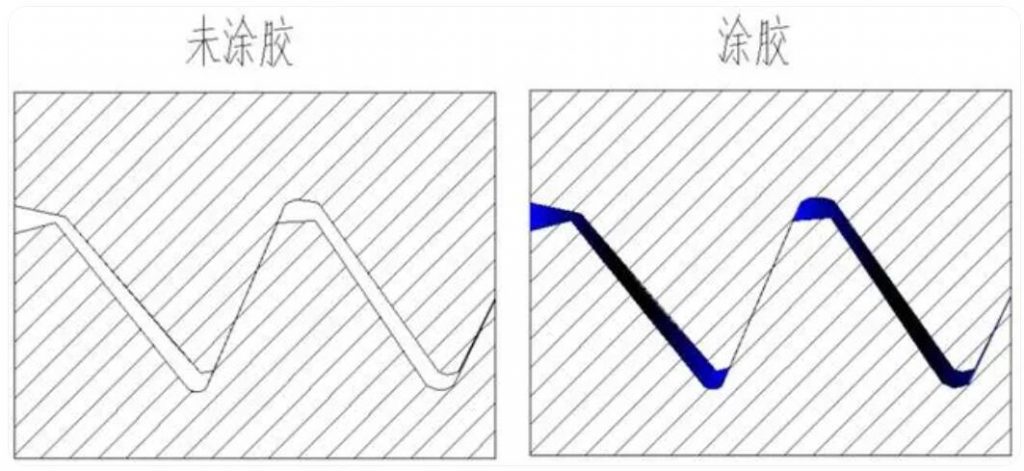

Metal screws are easily loosened or offline by impact vibration, and traditional mechanical locking methods are not ideal, while chemical locking methods are cheap and effective. If the screw is coated with screw glue for assembly, after curing, a strong plastic film is formed in the thread gap, so that the screw lock will not loosen.

Seal against leakage

Any plane can not be completely close contact, the need for leak-proof sealing, the traditional method is to use rubber, asbestos, metal and other gaskets, but due to aging or corrosion will soon leak. Instead of solid gaskets, screw glue can achieve close contact after curing, making the sealing more durable. The screw glue is used for sealing of threaded pipe joints and threaded plugs, sealing of flange matching surface, sealing of mechanical box joint surface, etc., and has good leak-proof effect.

Holding position

Cylindrical components, such as bearings and shafts, pulley and shaft, gear and shaft, bearings and seat holes, bushings and holes and other hole shaft combination accessories, previously without exception, the use of hot sleeve, cold pressure and other dimensional interference method to reassemble, supplemented by keys and dowel. This fixed method requires strict processing accuracy, and because of the different coefficient of thermal expansion, wear and corrosion are generated, and it is easy to loose. The screw glue can be used to fill the gap, and it is firm and durable after curing, stable and reliable. The method of anaerobic adhesive fixation can reduce the requirement of machining precision, simplify assembly operation, improve production efficiency, save performance consumption and processing cost. - How long does it take for anaerobic adhesive to fully cure?

Anaerobic adhesives do not contain solvents, so they must be cured. The curing of anaerobic adhesives must be in contact with active metal ions and an oxygen-free environment. Outside the bonding area, the anaerobic adhesive will not cure completely. Within the bonding area, the curing rate can be controlled by changing the product and the substrate. The curing speed can be increased by heating.

5, how much adhesive dosage is appropriate? How long is the storage life of anaerobic rubber products?

It is sufficient to meet the rubber filling requirements. Excessive use will not only cause waste, but also lead to adhesive migration, causing cleaning problems. Automatic applicator can control the amount of product on the line. Most anaerobic rubber products can guarantee product performance within two years after delivery.

In the threaded joint, when the tensile axial force is generated in the bolt, the nut should produce elastic radial expansion due to the radius component on the bevel of the thread teeth. Due to Poisson’s ratio, the bolt should produce elastic radial contraction.

Under the action of alternating load, due to the influence of the Angle of thread rise, there is a tendency of relaxed sliding along the inclined plane of thread teeth, and then the friction coefficient of the thread contact surface gradually decreases, and the final friction coefficient falls to the slip condition.

In order to inhibit the occurrence of this phenomenon, it is necessary to increase the anti-loosening treatment, for some detachable parts, the use of friction anti-loosening more, it is to increase the friction Angle to play the anti-loosening role, among which the thread is coated with anaerobic glue, after curing bonded in the thread, to achieve the purpose of anti-loosening.

01 Anaerobic adhesive curing principle

Formula:

TS is the torque generated by the Angle of thread rise

Tf is the torque generated by thread friction

Tw is the torque generated by friction of the support surface

d2 is the middle diameter of the thread

Is the Angle of thread rise

It is equivalent friction Angle

F is the axial force

DW is the equivalent friction diameter

UK is the friction coefficient of the support surface

Its loosening torque TL=Tf-Ts+Tw. After the anaerobic adhesive is cured, the anaerobic adhesive is attached to the mating thread, which similarly increases the friction coefficient of the contact surface at the thread. If loosening occurs, additional friction torque must be overcome.

Anaerobic adhesive is a monomeric adhesive solution with a monomer and a free group.

When in contact with air, oxygen has a large inhibition effect on the free group, so it can ensure that its liquid into a paste.

When it is filled at the mesh of the thread, due to the isolation of the air and the contact with the active surface of the metal, the free base triggers the polymerization of the monomer, into the polymer and automatic curing, the curing material fills all the gaps at the mesh of the thread, and builds a curing material in a few minutes, and the complete curing is completed in about 24 hours.

02 Classification of anaerobic adhesives

Under normal circumstances, according to the structure of the monomer, the category and strength of the monomer, the viscosity, the purpose of classification, its structure can be divided into four categories:

2.1 Ether type

The structure represented by triethylene glycol dimethacrylate.

2.2 Alkyd

Such as the United States Loctite 290 and mixed with fumarate bisphenol A unsaturated polyester Loctite 271, Loctite 277, Japan triple key 1030 and so on.

2.3 Epoxy grease

The reaction products of epoxy resins of various structures with methacrylic acid. Such as the United States Liqui-Lok-250, the domestic GY-340.

2.4 Polyurethane vinegar

Such as the United States Loctite 372, domestic GY-168 and so on. (2023-10-01)